About us

DAKAFORM, S. R. O.

DAKAFORM s.r.o. was founded in February 2015 as a family company focusing on the production and development of pressed parts and tools for cold forming. Our key motivation is to offer all our customers top services and comprehensive support in this area and thus permanently contribute to sustainability and prosperity and customer-supplier relationships.

We have a vision to be a lean company, maximally oriented to meet customer requirements.

Our goal is to produce products with a reasonable margin that will allow us to grow continuously and invest in our production facilities, in order to provide customers with the maximum possible portfolio and service.

Our company is certified according to ISO 9001

Production possibilities and scope

Our company offers the production of cold-formed parts in a wide range of processed materials.

We can process materials from 0.2 mm to 8 mm thick in the form of coils, sheets or rods

- cold rolled carbon steel

- stainless steel sheets and coils

- aluminum and copper coils, sheets and blanks

- nickel coils

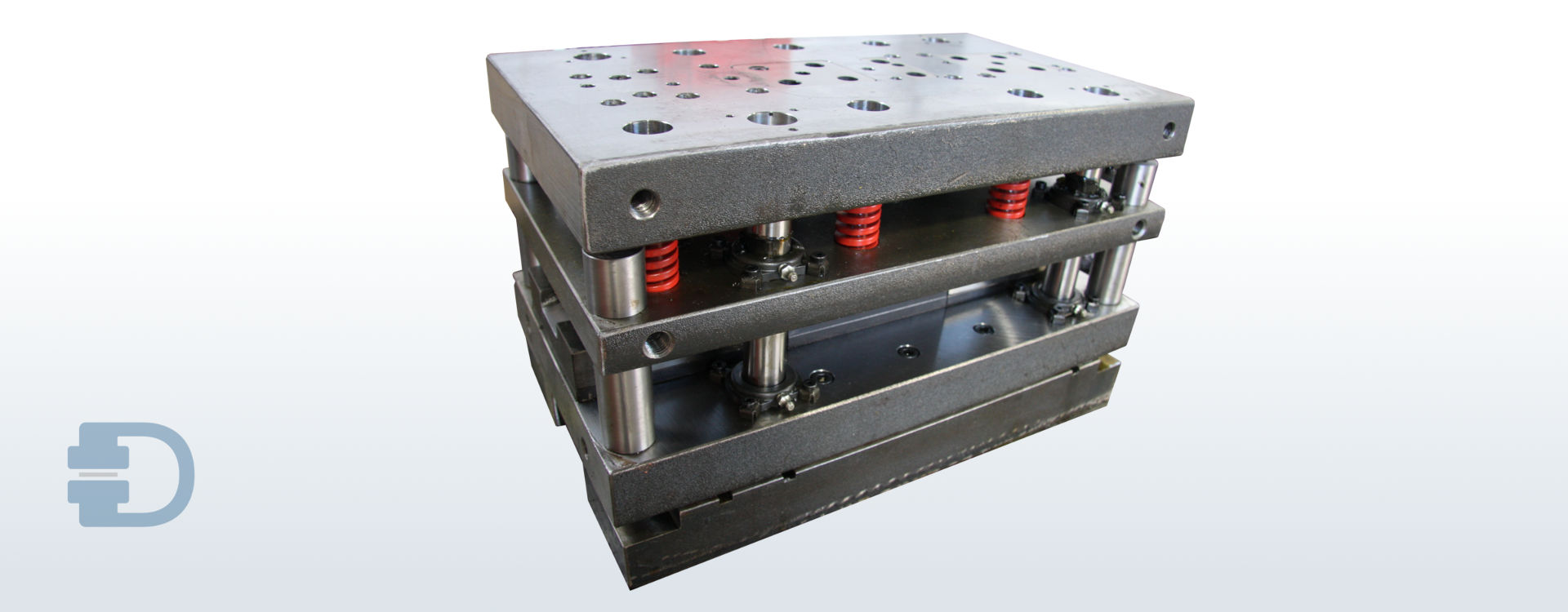

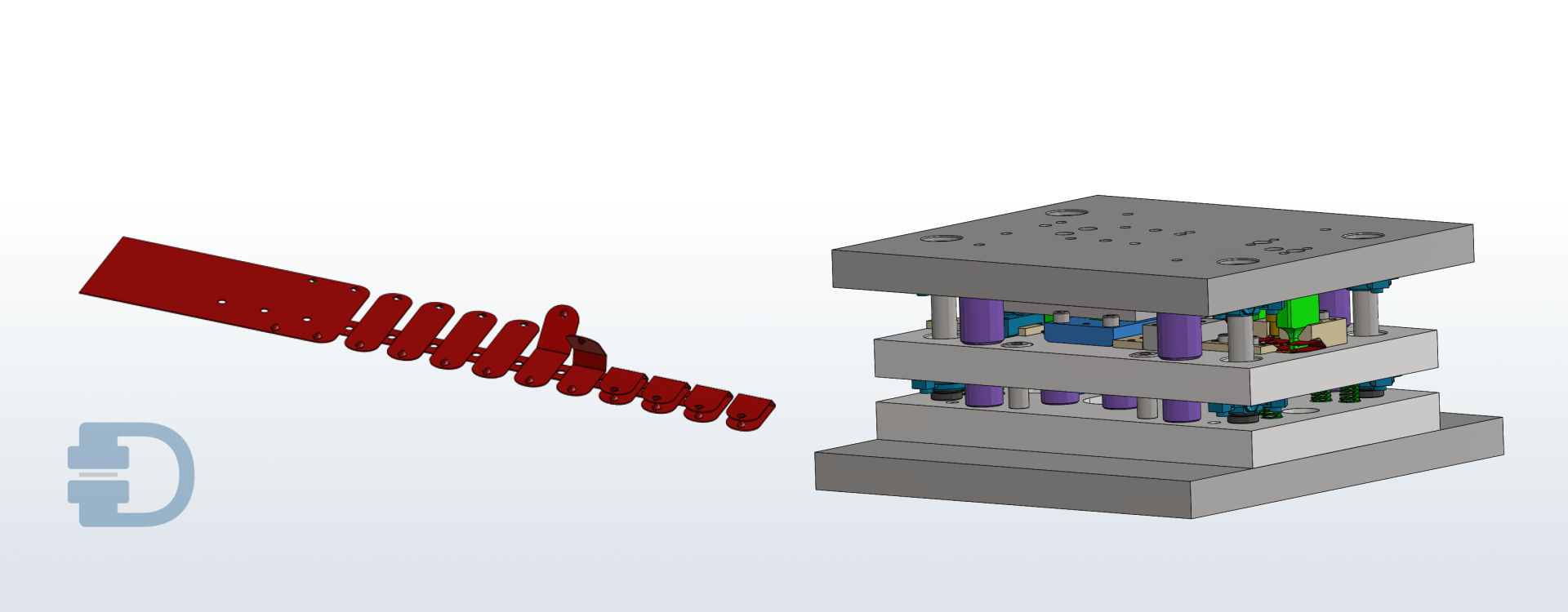

Progressive Stamping

It is a very effective industrial cold forming method designed for the production of parts in series from tens of thousands to millions per year. The input material is always a coil of the necessary material quality and dimensions.

Aluminium impact extrusion

Impact extrusion is a manufacturing process similar to extrusion and drawing by which products are made with a metal slug. The slug is pressed at a high velocity with extreme force into a die or mould by a punch.

Deep Drawing

Deep drawing is a sheet metal forming process by which a sheet metal blank is slightly clamped along its perimeter by a blank holder and radially drawn into a forming die by use of a punch without intentionally changing the thickness of the sheet.

Surface finish and finishing operations according to customer´s requirements

Degreasing, Zinc coating, Cataphoresis (KTL), Powder coating

Production of stamped parts in tools with manual insertion

This is the basic production method of stamped parts always using human force to handle parts and control the machine. As a rule, it is used for smaller series of shaped parts where it does not have the economic effect to invest in sophisticated tools and replace human work by robots or transfer and handling automats.

Product gallery

-

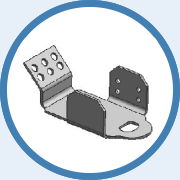

Clamping bracket

Material: steel strip S355 thickness 4 mm

Building industry -

Gate hinge

Material: galvanized th. 3 mm

Construction industry -

Bracket

Stamping

Material: stainless grade 1.4301 thickness 1 mm

Building industry -

Clamp for mobile fences

Progressive stamping +manual assembly

Material: zinc coated strip S250GD tlhickness 2 mm

Building industry -

Steel fence bracket

Material: zinc coated strip thickness 2 mm

Building industry -

Heating tube holder

Stamping+bending and assembly

Material: zinc coated strip DX51D thickness . 2 mm

Heating industry -

Door hinge

Stamped part

Material: steel plate thickness 3 mm

Heating industry -

Bracket for positionig

Progressive stamping

Material: zinc coated strip S250GD thickness 2 mm

Building industry -

Holder

Cutting and bending tool

Material: steel sheet th. 3

Heating and heating industry -

Bracket

Stamping

Material: zinc coated strip S250GD thickness 1 mm

Building industry -

Tube holder

Stamped part

Material: steel plate grade S355 thickness 6 mm

Agriculture -

Covering plate

Material: steel plate tlhickness 4 mm

Heating industry -

Deepdrawn rack feet

Deepdrawing

Steel grade S235 thickness 4 mm

Racking industry -

Bracket

Progressive stamping

Material: zinc coated strip thickness 1 mm

Building industry -

Door plate

Stamped part

Material: steel strip thickness 3 mm

Furniture industry -

Bracket for plastic boxes

Progressive stamping

Material: zinc coated strip thickness 0,7 mm

Racking industry -

Reinforcement tube

Material: zinc coated strip from 1 up to 3 mm

Building industry -

Tip plate for magnet

Progressive stamping

Material: tin plated strip thickness: 0,2 mm

Advertising industry -

Stamped part for racking

Stamped part

Material: steel strip S355 thickness 5 mm

Racking industry -

Stamped part

Progressive stamping

Material: stel strip garde S355 thickness 4 mm

Building industry -

Deep drawn laboratory can

Deepdrawing

Nickel strip Ni 99,5% thickness 0,2mm

Laboratory industry -

Nut

Progressive stamping

Flat steel th. 8 mm grade S235

Automotive industry -

Steel innsert for automotive roof window

Progressive stamping

Material: steel strip DC01 thickness: 1,2 mm

Automotive

Final customer: Webasto

Vehicle: Range Rover -

Stainless hook

Progressive stamping

Material: stainless steel th. 1 mm grade 1.4301

Extrerior blinds for windows -

Welded and machined steel assembly

Material: steel plates from 10 to 80 mm

Mining industry

Machinery

Progressive stamping

line Edelhoff 100

• press force: 10000 kN

• slide stroke: 20-120mm

• press table dimension: 810x860 mm

• number of strokes per minute: 30 - 150

• max. dimensions of coil: 520x3 mm

2x Progressive stamping and eccentric press line

Smeral LEN 63C

• press force: 6300 kN

• slide stroke: 20-120mm

• press table dimensions : 800x630 mm

• number of strokes per minute: 10 - 160

• max. dimensions of coil: 300x3 mm

Eccentric press

Weingarten 63

• press force: 6300 Kn

• slide stroke: 20-120mm

• press table dimensions: 700x620 mm

• number of strokes per minute: 120

Other company services

We are also able to provide following services in every phase of your project:

- Pressed parts optimization according to feasibility and cost efficiency

- Prototypes regarding to your drawing

Tools and dies design and dies supply - Production lines design and turnkey projects

- Advisory in a field of cold stamping and deep drawing

Contact

DAKAFORM s.r.o.

| Company headquarters: | Rybářská 365 735 62 Český Těšín Czech Republic |

| Company registration number: | 038 14 866 |

Company Management

Daniel Kaznica

Executive Director, Project Manager

E-mail: daniel.kaznica@dakaform.cz

Tel.: +420 720 329725

© 2021 DAKAFORM s.r.o.

Tvorba webových stránek Designsoft.cz